The Many Uses of Roller Bearings in Different Machines

As we all might know, a roller bearing is a mechanical component that supports connecting and rotating shafts to help with movement and mobilization within machinery. In short, it's a metal element used to reduce friction and accomplish crucial versatility from radial, axial, and thrust loads.

However, many of us don't quite know the breadth of their usage in machinery from complex applications such as in the motor industry to simple structures such as your everyday kitchen faucet. And these uses diversify in the industry with everyday ingenuity.

So, being the leading roller bearings supplier in Singapore, the team at SLS Bearings is here to provide some further insight into the fantastic design flexibility of an engineering component that is simply everywhere.

We are a Taper Roller Bearing supplier. If you are interested in our products, please contact us now!

We'll touch on the four major roller bearing types we provide here at SLS Bearings as well as their role, function, advantages and applications to help you make the right decision for your machine.

1. Cylindrical Roller Bearings

The first of the roller bearings is the cylindrical bearing characterized in name by its cross-section. The cage and inner ring of the roller bearing hold several micro-cylinders.

a) Role

As the leading roller bearings supplier in Singapore, it's important we advise that cylindrical roller bearings are also known through the mechanical industry as straight roller bearings. They are designed to allow for thermal expansion during the transmission of power to allow for high performance and durability even when placed under stressful conditions.

b) Function

The overall function of the cylindrical format from SLS Bearings is to use their conveyor-like maneuverability to minimize friction for heavy radial loads. As a primarily radial bearing (rather than an axial bearing) it is designed to withstand forces perpendicular to the access.

c) Advantages

Cylindrical bearings are one of the most sourced and applied components from your roller bearings supplier in Singapore. This is because, despite managing limited thrust loads, their radial design allows them to take high speeds and their uniformity allows them to be an interchangeable and repairable element.

d) Applications

Used in a wide variety of applications, cylindrical bearings can be seen in industries from power generation to the auto industry.

Used in a wide variety of applications, cylindrical bearings can be seen in industries from power generation to the auto industry.

Oil Pumps

Gearboxes

Motors

Steel Mills

Material Handling

Wind Turbines

Road Sweepers

Kingpins

Transmission Systems

Agricultural Equipment

Air Conditioning Compressors

Kitchen Faucets

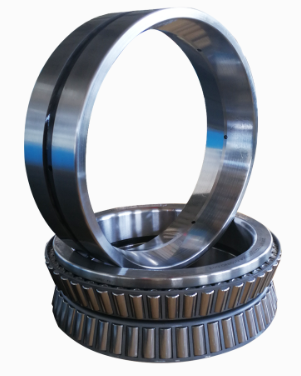

2. Tapered Roller Bearings

Tapered roller bearings are much like cylindrical roller bearings and carry a similar cross section. However, this component features an angular design allowing it to accomplish the handling of loads from both a radial and axial directions.

a) Role

The role of the taper roller bearing, with a cylindrical rolling element holding a tapered outer edge, is to handle a higher axial load. In fact, the bottom line to the taper roller bearings sold here at SLS Bearings would be that the more tapered the component, the higher the axial load it can accomplish.

b) Function

The operation specification of the tapered roller bearing is to use dual raceways that handle inertial forces and friction at an angle to increase the load handling from both directions. When two tapered roller bearings are used simultaneously, such as within vehicle wheels, they have higher durability.

c) Advantages

The outstanding benefits of the tapered roller bearings include being able to handle significant load capacity from both the axial and radial force directions of the metal components in use. Additionally, the tapered design allows for larger grease reservoirs between the radial and axial clearance zones.

d) Applications

At SLS Bearings, we supply tapered bearings for multiple variant usage. This is because of the application of single, double and four-row tapered bearings.

Vehicle Wheels

Rolling Mills

Gearboxes

Hosting Equipment

Mining Equipment

Agricultural Machines

Propeller Shafts

Sports Robots

3. Spherical Roller Bearings

Offering a mid-way solution between the cylindrical roller bearing and the ball bearing, the spherical bearing has a cross section with rolling components resembling a cask or barrel.

a) Role

When sourcing from a specialist roller bearings supplier in Singapore, the spherical roller bearing has the core role of taking dual-directional thrust and movement versatility. This is because the omni-tapered ends allow the rolling components to absorb friction transmission, even on a misalignment between the inner and outer rings.

b) Function

Introduced just a century ago, the primary function is to improve the carry capacity and reduce friction economy between the components while allowing for misalignment. It does this through having double-row raceways with added lubrication and a center flange to assist in high-pressure industrial uses.

c) Advantages

As already addressed, the diversification of the roller shape gives the advantages of accommodating for misalignment between components. This is accomplished through a cage that holds the rolling element in a staggered manner rather than linear. Additionally, this bearing can handle high bidirectional thrust.

d) Applications

With being able to handle misalignment, the team at SLS Bearings see spherical roller bearings being sourced for a number of varied mechanical industries. Especially for smaller components to help maintain frictionless movement between insubstantial elements.

Off-Road Vehicles

Oil Pumps

Food Processing machines

Gearboxes

Material Handling

Pulp Processing Equipment

Mechanical Fans

Continuous Casting Machines

Wind Turbines

Marine Propulsion

Drilling Units

Construction Machinery

We are a Taper Roller Bearing supplier. If you are interested in our products, please contact us now!

评论

发表评论