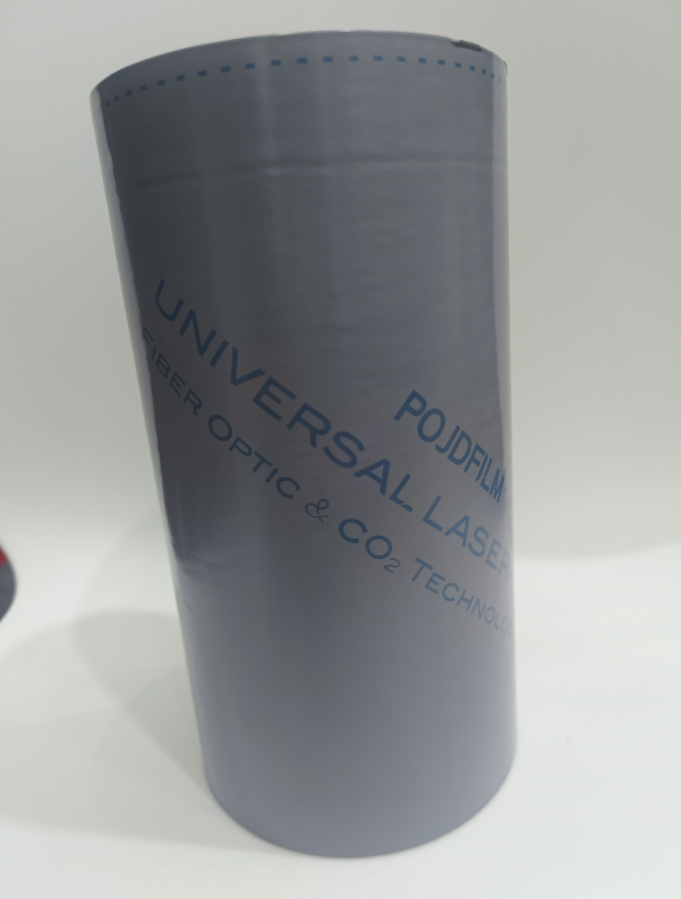

Laser Cutting Protective Films: Enhancing Precision and Efficiency

Laser cutting is a highly precise and efficient method of cutting a wide range of materials. It's used across various industries, from manufacturing to crafts, and it's essential to maintain the integrity of the materials being cut. That's where laser cutting protective films come into play.

What are Laser Cutting Protective Films?

Laser cutting protective films are specialized adhesive films that are applied to the surface of materials before the laser cutting process begins. These films serve multiple important purposes:

Protection: The primary function of these films is to protect the material from damage during the laser cutting process. Laser cutting can generate intense heat and can sometimes cause burn marks or residue on the material's surface. Protective films act as a barrier, preventing any harm to the material.

Clean Cuts: Protective films help ensure that the laser cuts are precise and clean. By preventing scorching or residue buildup, they contribute to the quality of the final product.

Reduced Maintenance: Laser systems can become dirty and require frequent cleaning due to residue buildup. Protective films minimize this need, saving time and maintenance costs.

How Do Laser Cutting Protective Films Work?

These protective films are typically made of a clear, thin, and heat-resistant material with an adhesive backing. They adhere to the material's surface, creating a protective layer. Here's how they work:

Application: The protective film is carefully applied to the material's surface before it's placed in the laser cutting machine. The adhesive ensures that it stays securely in place.

Laser Cutting: As the laser beam cuts through the material, it also penetrates the protective film. The film absorbs the heat and prevents it from affecting the material underneath.

Residue Prevention: Any residue or burn marks resulting from the laser cutting process are confined to the protective film, leaving the material unharmed.

Peel Off: After the cutting process is complete, the protective film can be easily peeled off, revealing a clean and undamaged surface.

Advantages of Using Laser Cutting Protective Films

The use of laser cutting protective films offers several advantages:

1. Enhanced Precision

By preventing damage to the material, protective films ensure that the laser cuts are precise, resulting in high-quality finished products.

2. Material Versatility

These films are compatible with a wide range of materials, including plastics, acrylics, wood, and metals, making them highly versatile.

3. Time and Cost Savings

Protective films reduce the need for frequent cleaning and maintenance of the laser cutting machine, saving both time and money.

4. Improved Aesthetics

The clean and residue-free cuts achieved with protective films enhance the overall aesthetics of the final product.

5. Extended Laser Lifespan

Laser systems often have a longer lifespan when they are protected from residue buildup, reducing maintenance and replacement costs.

In conclusion, laser cutting protective films are invaluable tools that enhance the precision, efficiency, and quality of laser cutting processes. By protecting materials and reducing maintenance requirements, they contribute to cost savings and overall improved results. When selecting a

plastic protective film, consider factors like material compatibility and thickness to ensure optimal performance.

评论

发表评论